3D printer nozzle

Approx $9.46 USD

The 3D printer nozzle is one of the most crucial components in a 3D printer, responsible for extruding the filament onto the print bed to create your designs layer by layer. A high-quality nozzle ensures precision, smooth surface finishes, and accurate prints. Whether you’re a hobbyist, professional designer, or manufacturer, the right nozzle can significantly impact the quality and efficiency of your 3D printing projects.

In this guide, we’ll explore the different types of 3D printer nozzles, their features, and how they influence the overall 3D printing process.

Types of 3D Printer Nozzles

Standard Brass Nozzle

Brass nozzles are the most commonly used type in 3D printing. They are highly durable, affordable, and offer excellent thermal conductivity, ensuring an efficient melt flow for various types of filaments. Brass nozzles are best for general-purpose printing with materials like PLA, ABS, and PETG.

- Pros: Affordable, widely available, high thermal conductivity

- Cons: Less durable with abrasive filaments like carbon fiber-infused filaments

Hardened Steel Nozzle

For users working with abrasive filaments like carbon fiber, glass-filled, or metal-infused filaments, a hardened steel nozzle is a better option. These nozzles are significantly more durable than brass nozzles and resist wear from abrasive materials.

- Pros: Highly durable, suitable for abrasive filaments

- Cons: Slightly lower thermal conductivity compared to brass

Stainless Steel Nozzle

Stainless steel nozzles are another great option for those printing with food-safe filaments or those requiring a non-reactive material. They are also highly resistant to corrosion and rust, making them ideal for printing in environments with high humidity.

- Pros: Corrosion-resistant, non-reactive, ideal for food-safe prints

- Cons: Lower thermal conductivity compared to brass and hardened steel nozzles

Ruby Nozzle

A ruby nozzle is a premium option designed for maximum durability and precision. With a ruby tip at the end of the nozzle, these provide the ultimate protection against abrasion and maintain excellent thermal conductivity. They are perfect for demanding applications where precision and wear resistance are essential.

- Pros: Long-lasting, extremely durable, high precision

- Cons: Expensive

Ceramic Nozzle

Ceramic nozzles are highly resistant to abrasion and are excellent for use with a variety of filaments, including flexible and composite filaments. Their unique properties allow them to maintain a consistent flow of material while producing high-quality prints.

- Pros: High wear resistance, great for a variety of filaments

- Cons: Can be brittle and require careful handling

Nozzle Size: What’s Right for You?

The size of the nozzle plays a significant role in the quality and speed of your 3D prints. The most common nozzle size is 0.4mm, but you can find nozzles ranging from 0.2mm to 1.0mm. Each size offers distinct benefits:

Smaller Nozzles (e.g., 0.2mm, 0.3mm)

- Precision: Smaller nozzles allow for more detailed prints, with fine layers and higher resolution.

- Speed: Printing with smaller nozzles can be slower, as it requires more time to complete each layer.

- Best for: Intricate designs, high-resolution prints, or parts that require fine detail.

Larger Nozzles (e.g., 0.8mm, 1.0mm)

- Precision: Larger nozzles are less suited for highly detailed prints but are ideal for faster prints and larger objects.

- Speed: Larger nozzles extrude more filament, resulting in faster prints.

- Best for: Prototyping, large models, and projects where speed is more important than fine details.

Choosing the Right Nozzle for Your 3D Printer

When choosing the right 3D printer nozzle, consider the following factors:

- Filament Type: Some materials, especially abrasive filaments, require nozzles made from hardened steel, ceramic, or ruby to prevent wear and tear.

- Print Detail: For high-precision prints, opt for smaller nozzles (0.2mm to 0.4mm). For larger, less detailed objects, consider larger nozzles.

- Print Speed: Larger nozzles allow for faster printing speeds, while smaller nozzles are better for detailed work.

- Durability: If you print frequently with abrasive filaments or need to maximize nozzle lifespan, choose a hardened steel or ruby nozzle.

Benefits of Using a High-Quality 3D Printer Nozzle

Improved Print Quality

A high-quality nozzle ensures a smoother extrusion process, resulting in better adhesion, crisper details, and smoother surfaces. It minimizes common issues like clogging and stringing, contributing to an overall higher print quality.

Increased Print Speed

Nozzles with larger diameters extrude more filament per layer, enabling faster print speeds. If time is of the essence, switching to a larger nozzle can help you complete larger projects more efficiently.

Longer-Lasting Prints

Using a high-durability nozzle, like a hardened steel or ruby nozzle, ensures longer-lasting prints, especially when working with abrasive filaments. It also minimizes the need for frequent replacements, which helps reduce downtime and maintenance costs.

How to Maintain Your 3D Printer Nozzle

Proper maintenance of your 3D printer nozzle is essential for consistent, high-quality prints. Here are some tips to keep your nozzle in top shape:

- Clean Regularly: Clogged nozzles can lead to printing errors. Regularly clean the nozzle using a wire brush or a needle tool.

- Check for Wear: Inspect your nozzle for signs of wear, especially if you frequently use abrasive filaments.

- Use a Nozzle Cleaning Kit: Specialized kits can help clear any build-up or blockage in your nozzle.

- Replace When Necessary: If your nozzle is damaged or worn out, replace it with a compatible one to avoid printing issues.

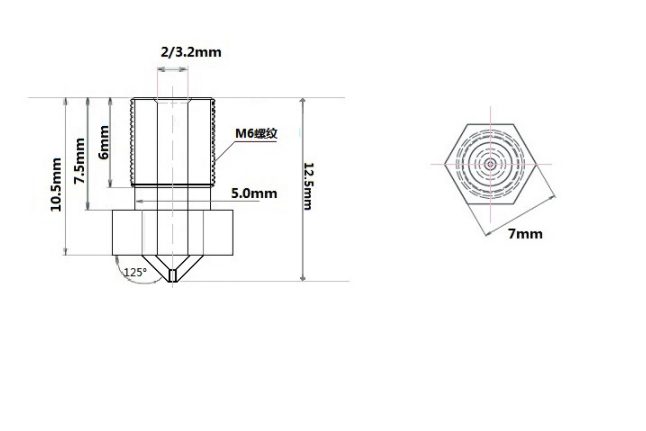

Specification size: 7mm*12mm

Material: Brass

Color: Brass

Nozzle accuracy: 0.20.3 0.4 0.5 0.8 mm/1.75/0.20.3 0.4 0.5 mm/3.0

Thread: M6 thread

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

.jpg)

.jpg)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)