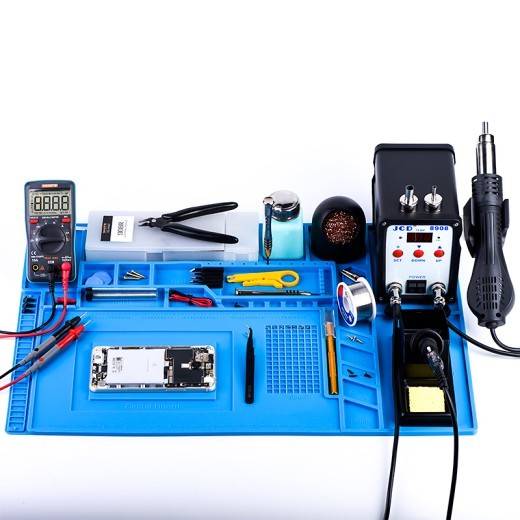

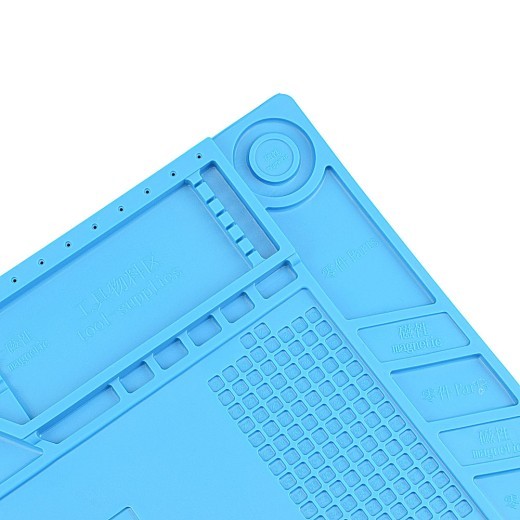

Anti static heat insulation welding work pad

Approx $34.29 USD

Introduction to the Anti-Static Heat Insulation Welding Work Pad

The Anti-Static Heat Insulation Welding Work Pad is a versatile and essential tool for welding, soldering, and electronics repair. Designed to protect your workspace from heat damage and prevent static buildup, this pad enhances safety and efficiency in professional and DIY environments. Whether you’re working on intricate electronics or heavy-duty welding projects, this durable and heat-resistant mat is the perfect addition to your toolkit.

H2: Key Features of the Anti-Static Heat Insulation Welding Work Pad

1. Anti-Static Properties

The pad is made from materials that effectively dissipate static electricity, protecting sensitive electronic components from damage during soldering or repair.

2. High Heat Resistance

With a heat resistance of up to 500°C or higher (depending on the model), the pad shields your workspace from burns and damage caused by soldering irons or welding torches.

3. Non-Slip Surface

The pad’s textured surface ensures stability, keeping your tools and workpieces securely in place while you work.

4. Durable Construction

Made from high-quality silicone or composite materials, the pad resists wear and tear, ensuring long-lasting performance in demanding environments.

5. Multi-Compartment Design

Some models feature compartments and slots for organizing tools, screws, and components, keeping your workspace tidy and efficient.

6. Portable and Flexible

The lightweight and flexible design allows for easy transport and storage, making the pad ideal for on-the-go professionals and hobbyists.

7. Easy to Clean

The surface is easy to wipe clean, ensuring a neat and hygienic workspace after every use.

H2: Why Choose the Anti-Static Heat Insulation Welding Work Pad?

1. Tailored for New Zealand’s Needs

Whether you’re working in an electronics lab, a garage, or a DIY setup, this pad meets the diverse requirements of New Zealand’s professionals and hobbyists.

2. Enhanced Safety

The anti-static and heat-resistant properties minimize the risk of accidents, protecting both your workpieces and your workspace.

3. Improved Workflow

With its non-slip surface and optional tool organization features, the pad enhances efficiency by keeping tools and components in place.

4. Durable and Reliable

Built to withstand high temperatures and frequent use, the pad ensures consistent performance over time.

5. Affordable and Versatile

Combining safety, functionality, and durability, the pad offers excellent value for money.

H2: Maintenance and Care Tips for Your Welding Work Pad

To ensure your work pad remains in top condition, follow these care tips:

- Clean After Use: Wipe the pad with a damp cloth or mild cleaning solution to remove residue, flux, or debris.

- Inspect Regularly: Check for signs of wear or damage, such as cracks or burns, and replace the pad if necessary.

- Avoid Sharp Tools: Minimize contact with sharp objects to prevent punctures or scratches on the surface.

- Store Properly: Roll or lay the pad flat in a cool, dry place to avoid warping or damage.

- Use Within Limits: Adhere to the recommended heat resistance and weight limits to maintain durability.

H2: Popular Applications for the Welding Work Pad

1. Electronics Repair

Protect delicate electronic components from static discharge and heat damage during soldering or assembly.

2. Welding Projects

Use the pad as a heat-resistant surface for welding small parts, ensuring safety and stability.

3. Soldering and Desoldering

Keep your workspace protected while soldering wires, circuit boards, or other components.

4. DIY and Hobby Projects

Ideal for crafting, repairing, or building projects that require heat-resistant and anti-static properties.

5. Automotive Work

Use the pad for repairing or assembling small parts in automotive maintenance tasks.

H2: How to Use the Anti-Static Heat Insulation Welding Work Pad

1. Set Up Your Workspace

- Place the pad on a stable surface in your workspace.

- Ensure the pad is clean and free of debris before starting.

2. Organize Your Tools

- If the pad has compartments, use them to arrange tools, screws, and components for easy access.

3. Perform Your Task

- Conduct your welding, soldering, or assembly task directly on the pad, relying on its heat-resistant and anti-static properties for safety.

4. Clean and Store

- After use, clean the pad with a damp cloth and store it flat or rolled up in a safe place.

Type: soldering iron pad

Material: silica gel

Thickness 5 (mm)

Hardness: low

Resistance value L: 100 (Ω)

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

.webp)

.webp)

.webp)

.webp)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)