Metal Heavy Welding Locomotive

Approx $141.91 USD

Introduction to the Metal Heavy Welding Locomotive

The Metal Heavy Welding Locomotive is a state-of-the-art welding machine engineered for large-scale industrial and automotive applications. This robust piece of equipment is designed to handle the most demanding welding tasks, offering precision and reliability. Perfect for New Zealand’s manufacturing, construction, and transportation industries, the welding locomotive ensures high-performance results in the fabrication and repair of heavy metal structures.

H2: Key Features of the Metal Heavy Welding Locomotive

1. Heavy-Duty Construction

Built with high-grade metal, the welding locomotive is designed to withstand rigorous use in industrial environments, ensuring long-lasting durability.

2. High Welding Capacity

Capable of handling thick metals and large surfaces, this machine is ideal for heavy-duty welding applications, including structural steel and locomotive repairs.

3. Precision Welding Control

Advanced controls allow for precise adjustments in welding speed, temperature, and technique, ensuring clean and accurate welds.

4. Multi-Process Compatibility

Supports multiple welding processes such as MIG, TIG, and Stick, providing versatility for different project requirements.

5. Powerful Motor and Drive System

The locomotive is equipped with a robust motor that ensures consistent performance and efficient operation, even during prolonged use.

6. Enhanced Safety Features

Integrated safety mechanisms, such as overload protection and heat-resistant components, ensure safe operation for users and equipment alike.

7. Portability with Heavy-Duty Wheels

Despite its robust design, the welding locomotive features heavy-duty wheels for easy mobility across worksites.

8. Energy Efficient

Designed with modern energy-saving technology, the machine reduces power consumption without compromising performance.

H2: Why Choose the Metal Heavy Welding Locomotive?

1. Tailored for New Zealand Industries

From construction to transportation, this welding locomotive meets the diverse needs of New Zealand’s industrial and automotive sectors.

2. Unmatched Durability

With its sturdy construction and heat-resistant components, this machine is built to endure heavy workloads and harsh conditions.

3. Precision and Efficiency

Advanced controls and powerful welding capabilities ensure professional-grade results with minimal rework.

4. Versatility in Applications

With support for multiple welding processes and compatibility with a variety of metals, this locomotive adapts to a wide range of tasks.

5. Cost-Effective Investment

Offering durability and efficiency, the welding locomotive reduces downtime and maintenance costs, making it a valuable long-term investment.

H2: Maintenance and Care Tips for the Welding Locomotive

To ensure optimal performance and extend the lifespan of your welding locomotive, follow these maintenance tips:

- Regular Cleaning: Remove dust, debris, and welding spatter from the machine after each use.

- Inspect Components: Check cables, connectors, and internal components for wear or damage, and replace as necessary.

- Lubricate Moving Parts: Apply appropriate lubricants to ensure smooth operation of the motor and drive system.

- Test Safety Features: Periodically test overload protection and other safety mechanisms to ensure proper functionality.

- Store in a Dry Location: Protect the machine from moisture and extreme temperatures when not in use.

H2: Popular Applications for the Welding Locomotive

1. Heavy Metal Fabrication

Perfect for constructing large metal structures such as beams, frames, and industrial equipment.

2. Automotive and Locomotive Repairs

Repair and fabricate parts for vehicles, trains, and other heavy-duty machinery with precision and efficiency.

3. Construction Projects

Handle structural welding tasks on-site, including bridges, buildings, and other large-scale construction projects.

4. Shipbuilding

Weld large sections of metal hulls and ship components with ease and accuracy.

5. Industrial Maintenance

Perform heavy-duty repairs and maintenance on factory equipment, pipelines, and industrial systems.

H2: How to Use the Metal Heavy Welding Locomotive

1. Set Up the Machine

- Position the welding locomotive on a stable surface or track.

- Connect the appropriate welding tools and ensure secure connections.

2. Adjust Settings

- Select the desired welding process (MIG, TIG, or Stick) and adjust speed, temperature, and feed settings as needed.

3. Prepare the Workpiece

- Clean the metal surface to remove rust, grease, or debris.

- Align and secure the workpiece to ensure stability during welding.

4. Begin Welding

- Activate the machine and guide the welding torch along the joint, maintaining steady speed and pressure for clean welds.

5. Shut Down and Inspect

- Turn off the machine and allow it to cool before inspecting the weld for quality and strength.

Specification

Product Information

Item Code:W1422P199655

Product Type:General Item

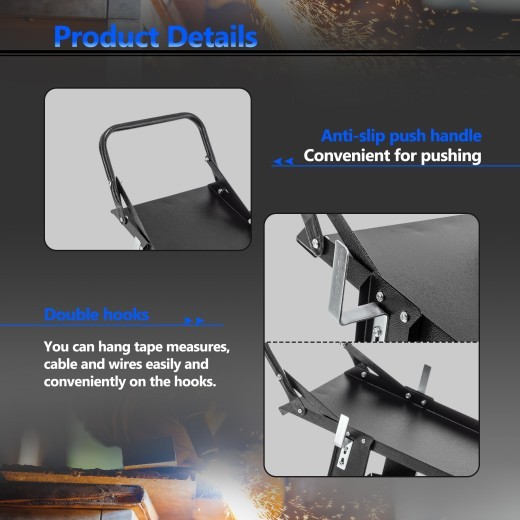

Product Name:Welding Cart, 3-Tier Welder Cart Heavy Duty with 400Lbs Static Weight Capacity, 360° Swivel Wheels, Tank Storage Safety Chains, Rolling MIG Welder Cart for TIG, ARC, MMA Welding Machine

Main Color:Black

Main Material:Metal

Product Dimensions

Assembled Length (in.):28.00

Assembled Width (in.):15.80

Assembled Height (in.):34.35

Weight (lbs.):20.00

Package Size

Length (in.):28.74

Width (in.):12.20

Height (in.):3.74

Weight (lbs.):21.61

Product Features

- 【Strong Weight Capacity】3-tier welding cart can effortless handle various heavy loads, with 400LBS maximum static weight capacity and 370LBS maximum dynamic weight capacity. Heavy-duty welder cart is suitable for a variety of welding tasks such as manual welding, gas shielded welding, and argon arc welding.

- 【Premium Material】This welding cart is made of high-quality steel, which is durable and can be used reliably for a long time. The surface of the welding car is painted with black paint, which not only looks good, but also resists rust and corrosion.

- 【3-layer Open Storage Space】This welding cart has 3 layers of open storage space, which provides a large space for placing welding tools, you can put the welding tools inside, which is convenient to carry. Sloping top shelf for easy access to welder controls, spacious rear shelf with 2 safety chains to secure gas cylinders

- 【Welding Cart with 4 Wheels】This welding cart is equipped with 4 front and rear casters of different sizes, which move smoothly and turn the direction easily. The two front wheels can be rotated 360°, and the two large rear wheels provide optimum stability and are very labor-saving

Description

Specification

| tem Type | 3-Tier Welding Cart |

| Maximum Weight Capacity | 400LBS(Static); 370LBS(Dnamic) |

| Item Dimensions | 28 x 15.8 x 34.25 in |

| With Casters | Yes, 360° Swivel Wheels |

| Fit For Welding Machine | TIG, ARC, MMA, Plasma Cutter |

| Side Brackets | 4 |

| Gas Cylinder Slots | 2 |

| Safety Chains | 2 |

| Material | Metal Frame, Rubber iron wheels |

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

.webp)

.webp)

.webp)

.webp)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)