Self-locking MIG-500 cooling water tank socket

Approx $17.73 USD

Introduction to the Self-Locking MIG-500 Cooling Water Tank Socket

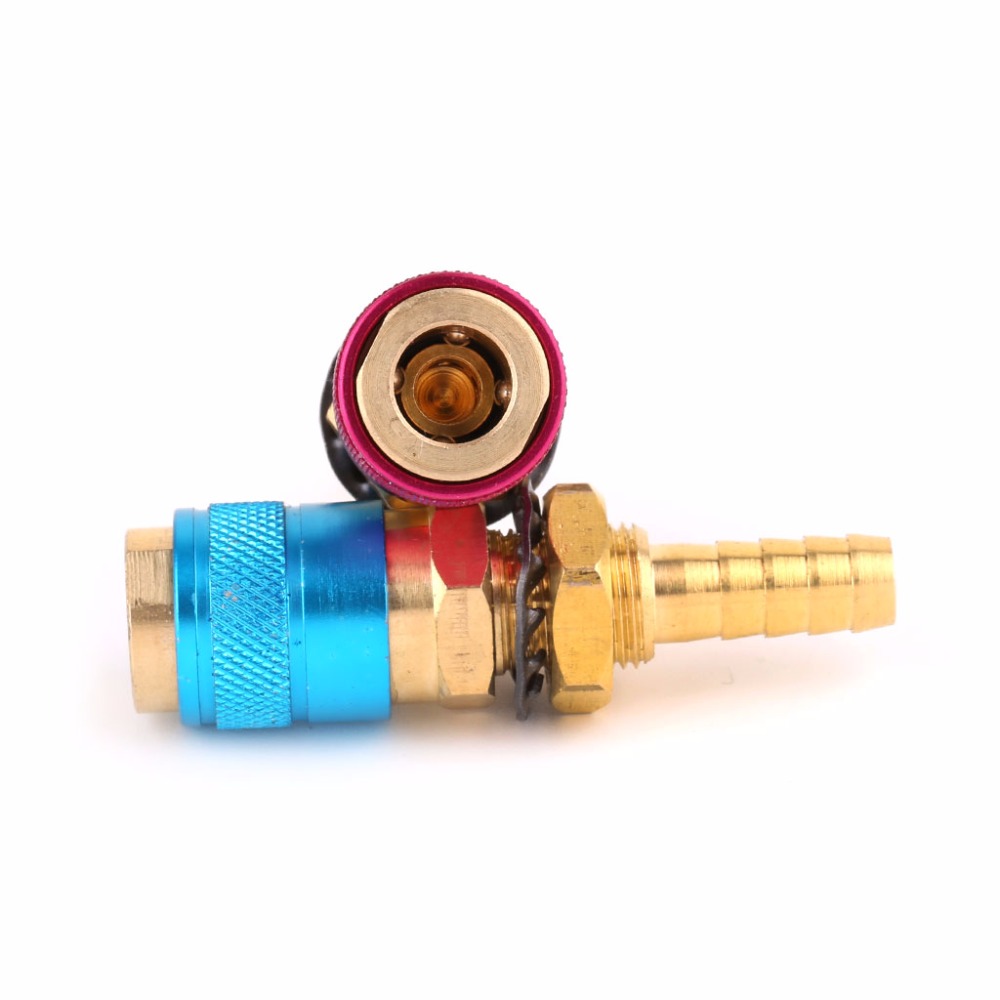

The Self-Locking MIG-500 Cooling Water Tank Socket is a vital component designed to ensure efficient cooling and optimal performance for MIG-500 welding machines. This advanced socket, engineered with a self-locking mechanism, secures the water line connections to prevent leaks and maintain uninterrupted cooling, even during intensive welding sessions. Built to withstand the demands of high-temperature welding environments, the MIG-500 cooling socket is indispensable for New Zealand welders looking to protect and prolong their welding equipment. With its color-coded design, durability, and ease of use, this cooling water tank socket is the ideal solution for anyone in the welding industry seeking a reliable cooling system connector.

H2: Key Features of the Self-Locking MIG-500 Cooling Water Tank Socket

1. Self-Locking Mechanism for Secure Connection

The self-locking feature of this socket ensures that water hoses remain firmly connected throughout the welding process, reducing the risk of disconnection or leakage. By securely locking into place, this mechanism allows the cooling system to operate effectively, keeping the MIG-500 machine at optimal temperatures. This feature is particularly valuable for professionals engaged in extended welding projects where maintaining a constant cooling flow is essential.

2. Durable Construction for Longevity in Harsh Environments

Constructed from high-quality, durable metals, the MIG-500 cooling socket is designed to endure the harsh conditions typical of welding environments. Its metal composition provides resilience against high temperatures, exposure to welding spatter, and frequent use. This durability ensures that the socket remains reliable over time, even under regular, demanding conditions, making it a long-term investment for any workshop or industrial setting.

3. Leak-Free Design for Enhanced Safety and Efficiency

A leak-free connection is critical for both safety and the efficient functioning of the cooling system. The Self-Locking MIG-500 Cooling Water Tank Socket is engineered to create a tight, secure seal around the water line, preventing any unwanted leaks. This design minimizes water loss, maintains consistent cooling, and reduces the risk of overheating. For New Zealand welders prioritizing equipment safety and reliability, the leak-free feature is a must-have.

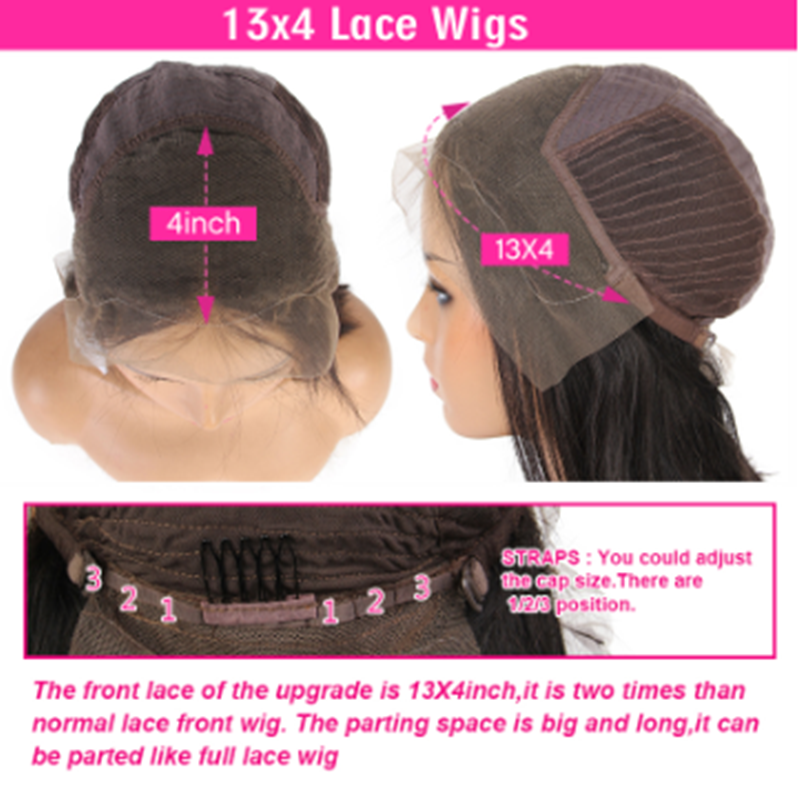

4. Color-Coded for Easy Installation and Maintenance

The socket comes in red and blue variants, allowing users to easily distinguish between different water lines during installation and maintenance. This color-coding feature helps welders avoid mixing up inlet and outlet lines, ensuring the proper flow of water through the cooling system. The intuitive color coding streamlines setup and reduces potential errors, particularly in fast-paced work environments.

5. Compact and Lightweight for Easy Handling

Measuring approximately 62mm in length, this socket is compact and lightweight, making it easy to handle and install. Despite its small size, it delivers reliable performance, offering welders an effective cooling line solution that doesn’t add unnecessary bulk. This compact design also makes it easy to transport and store, fitting neatly into toolkits or welding stations.

6. Compatible with MIG-500 Cooling Systems

The Self-Locking Cooling Water Tank Socket is specifically designed for MIG-500 welding machines, ensuring seamless compatibility with standard cooling systems used in these models. By providing a secure connection for cooling water tanks, this socket helps maintain a stable temperature during high-intensity welding operations, enhancing the overall efficiency and durability of MIG-500 machines.

H2: Why Choose the Self-Locking MIG-500 Cooling Water Tank Socket?

1. Ideal for Maintaining Optimal Cooling in High-Performance Welding

MIG-500 welding machines are often used in heavy-duty applications, which can generate significant heat over extended periods. The Self-Locking Cooling Water Tank Socket plays a crucial role in maintaining optimal cooling, allowing the machine to perform at its best without the risk of overheating. For welders working on intense or prolonged projects, this component helps ensure consistent machine performance.

2. Enhanced Safety in the Workplace

With its secure locking mechanism and leak-free design, the MIG-500 cooling socket contributes to a safer workplace by reducing the risk of leaks that could lead to slips, falls, or electrical issues. Proper cooling is essential for the safe operation of welding machines, as it helps prevent overheating and equipment malfunction. The socket’s design prioritizes safety, making it an asset for any professional welding setup.

3. Durability for Cost-Effective Long-Term Use

Given its robust construction, the Self-Locking MIG-500 Cooling Water Tank Socket is a cost-effective choice for welders who value durability. Frequent replacements can lead to higher costs and downtime, but this socket’s resilience minimizes such interruptions, saving money over time. Its high-quality materials and secure locking capabilities ensure consistent performance, making it a worthwhile investment.

4. Simple Installation and Maintenance

The color-coded design and compact size make the installation and maintenance of this socket straightforward, allowing welders to focus more on their work and less on setup. For new users, the color-coded red and blue options make it easy to differentiate between cooling lines, simplifying installation and reducing the chance of errors. Maintenance is also simplified, as the self-locking feature makes it easy to disconnect and inspect the hoses without struggling to undo fittings.

5. Perfect for New Zealand’s Professional Welding Industry

Designed to meet the needs of New Zealand’s professional welders, this cooling socket provides a reliable, high-quality solution for maintaining the efficiency of MIG-500 machines. The focus on safety, durability, and precision makes it ideal for local welding professionals in various industries, including construction, manufacturing, and industrial fabrication. The socket is a dependable choice for ensuring welding operations run smoothly, even under challenging conditions.

H2: Maintenance and Care Tips for Your Self-Locking MIG-500 Cooling Water Tank Socket

To keep your Self-Locking Cooling Water Tank Socket in optimal condition, follow these care and maintenance tips:

-

Inspect Regularly for Wear and Tear: Regularly check the socket for signs of wear or damage, particularly around the

self-locking mechanism and sealing areas. Replace the socket if you notice any signs of deterioration to ensure reliable performance.

-

Keep Free of Debris and Dirt: Dust or metal debris can affect the locking mechanism and potentially compromise the socket’s

seal. Clean the socket periodically to prevent blockages or buildup that could interfere with a secure connection.

-

Check Connections for Tightness: Before each use, ensure that the socket is securely connected to the cooling lines. A

loose connection can cause leaks and reduce the effectiveness of the cooling system.

-

Avoid Exposure to Excessive Heat: Although designed for high-temperature environments, avoid exposing the socket to open

flames or extreme heat sources. Excessive heat may cause damage to the material and impact performance over time.

- Replace with Compatible Parts Only: When replacing any parts of the cooling system, ensure compatibility with MIG-500 models to avoid any mismatched connections that could lead to cooling inefficiency or leaks.

material: metal

Color: red, blue

Length: 62 mm / 2.44 inches

Quantity: 1 set

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

.webp)

.webp)

.webp)

.webp)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)