Wrong Edge Inspection Ruler For Welding Seam Of Large Height And Low Gauge

Approx $28.38 USD

Introduction to the Wrong Edge Inspection Ruler for Welding Seam Height and Low Gauge Measurement

The Wrong Edge Inspection Ruler is a precision measurement tool specifically designed to inspect the welding seam height and low gauge discrepancies in large-scale welding projects. Essential for welders, inspectors, and quality control professionals, this ruler allows for accurate measurements of uneven welding edges, ensuring compliance with safety standards and quality benchmarks. With its robust construction and precise markings, this inspection ruler is perfect for assessing weld seams on structures, pipelines, and heavy-duty equipment. In industries such as construction, shipbuilding, and manufacturing across New Zealand, this tool is invaluable for maintaining high-quality welding standards.

H2: Key Features of the Wrong Edge Inspection Ruler

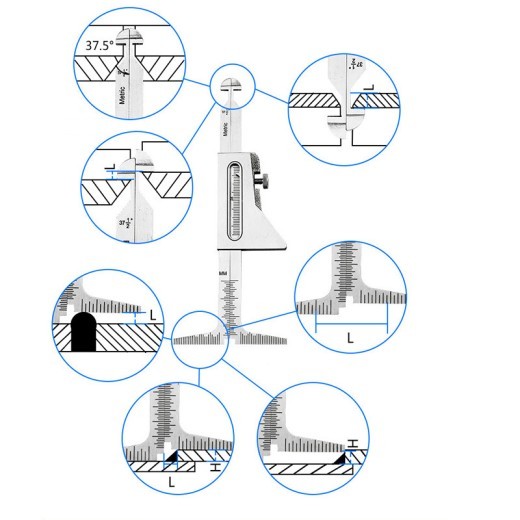

1. Precision Measurement for Welding Seam Height and Gauge

The inspection ruler offers accurate measurement for both welding seam height and low gauge differences, allowing users to inspect uneven edges efficiently. It is calibrated to deliver precise readings, making it easier to assess the quality of welds and identify any deviations from standard requirements. This precision is essential for quality control, particularly in projects that require adherence to strict welding standards.

2. Durable Construction for Heavy-Duty Use

Made from high-grade stainless steel or aluminum, the inspection ruler is built to withstand regular use in industrial environments. Its robust construction ensures it remains resistant to wear, corrosion, and deformation, making it suitable for use in harsh conditions such as outdoor welding sites or heavy manufacturing facilities. The durability guarantees long-lasting performance and reliable measurements over time.

3. Clear and Easy-to-Read Markings

The ruler features clearly engraved or printed markings that are easy to read, even in low-light conditions. The markings are precisely calibrated to measure welding seam height and gauge with accuracy. This clarity is particularly useful for inspectors and welders who need quick, accurate readings in busy or dimly lit work environments.

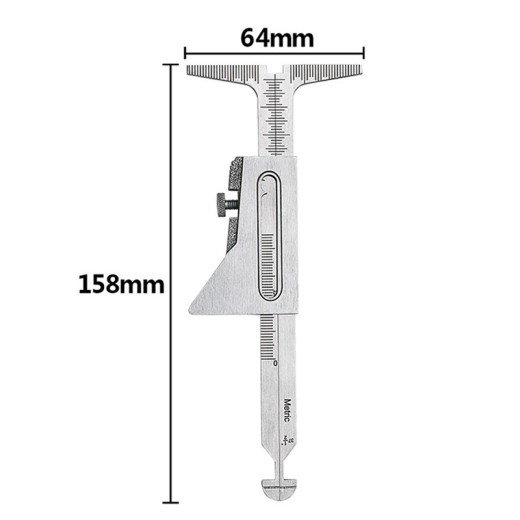

4. Portable and Compact Design for Easy Use

Despite its robust construction, the ruler is compact and portable, making it easy to carry around in toolkits or pockets. Its lightweight design ensures that users can conveniently transport it between welding sites, providing a handy solution for on-the-go inspection. This portability makes it ideal for welders and inspectors working on large structures or in different locations.

5. Ergonomic Design for Comfortable Handling

The ruler is designed for ease of use, with an ergonomic shape that makes it comfortable to hold and maneuver around weld seams. The design allows users to measure welding seams accurately without straining their hands, which is particularly beneficial for tasks that require repetitive measurements or extended inspection periods.

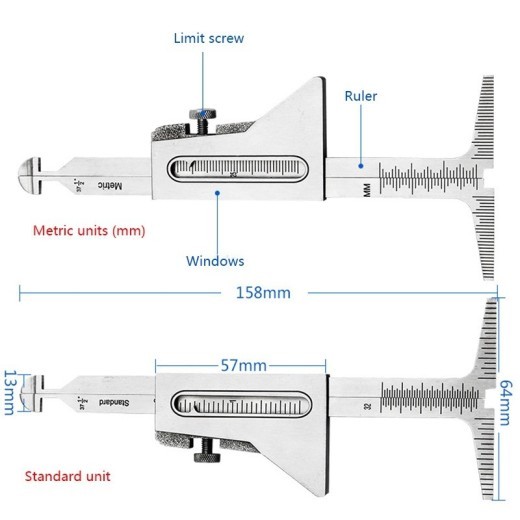

6. Multi-Scale Measurements for Versatile Use

This inspection ruler often includes multiple scales, enabling it to measure both metric and imperial units. This versatility is ideal for projects that follow international standards or require compatibility with various measurement systems. The multi-scale feature makes it adaptable for a range of welding applications and user preferences.

H2: Why Choose the Wrong Edge Inspection Ruler for Welding Seam and Gauge Measurement?

1. Essential for Quality Control in Welding Projects

This inspection ruler is indispensable for quality control teams, ensuring weld seams meet height and gauge specifications. By providing accurate measurements, it helps maintain consistent welding quality and reduces the risk of structural weaknesses caused by uneven seams. This tool is ideal for industries where weld quality is critical, such as construction, shipbuilding, and industrial manufacturing.

2. Perfect for Large-Scale and Heavy-Duty Welding Applications

Designed for large-scale welding projects, this ruler is suitable for inspecting seams on large metal structures, pipelines, and heavy equipment. The robust design and high accuracy make it an ideal tool for challenging welding applications, where precision and durability are essential for reliable measurements.

3. Improves Efficiency in Inspection and Measurement

With clear markings and ergonomic handling, the inspection ruler allows welders and inspectors to take quick, accurate measurements without delay. This efficiency is valuable in industrial settings, where time is critical, and inspections need to be thorough but streamlined. The tool’s portability and ease of use make it efficient for frequent inspections on multiple welding seams.

4. Supports Compliance with Welding Standards

The ruler helps ensure that welding seams comply with industry standards and safety guidelines. Accurate measurements of seam height and low gauge deviations are critical for meeting quality requirements, reducing the risk of structural failures and ensuring compliance with regulatory standards. This tool is essential for professionals committed to quality and safety.

5. Durable and Reliable for Long-Term Use

Constructed from high-quality materials, this inspection ruler is built to endure frequent use in demanding environments. Its durability ensures consistent performance and accuracy over time, making it a cost-effective investment for professionals who require reliable tools for welding inspection.

H2: Maintenance and Care Tips for Your Wrong Edge Inspection Ruler

To keep your inspection ruler in excellent condition, follow these care tips:

-

Clean Regularly: Wipe down the ruler after each use to remove any welding residues, dust, or debris. Regular cleaning helps

maintain visibility of the markings and ensures accurate measurements.

-

Store in a Safe Place: When not in use, store the ruler in a protective case or toolbox to prevent scratches or bending.

This helps preserve its durability and accuracy.

-

Avoid Exposure to Extreme Temperatures: Prolonged exposure to high temperatures can affect the calibration of the ruler.

Avoid leaving it near welding equipment or in direct sunlight to prevent warping or degradation.

- Inspect for Wear and Tear: Periodically check the ruler for any signs of wear, particularly around the measurement markings. Replace it if markings become unclear or the ruler shows signs of deformation, ensuring continued accuracy.

Product information:

Model: Weld Height Gauge

Type: Welding seam wrong side ruler

Measuring range: 0-32mm

Accuracy: 0.1mm

Scope of application: Products and components with high welding quality requirements

Material: Stainless steel

Size information:

Size: 166*70*25mm

Packing list :

Weld Height Gauge

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

.webp)

.webp)

.webp)

.webp)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

ulva-Logo.jpg)

.jpeg)

.png)

.png)